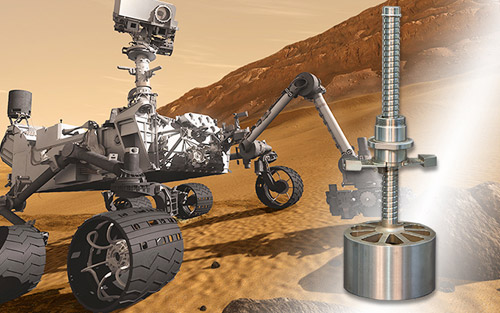

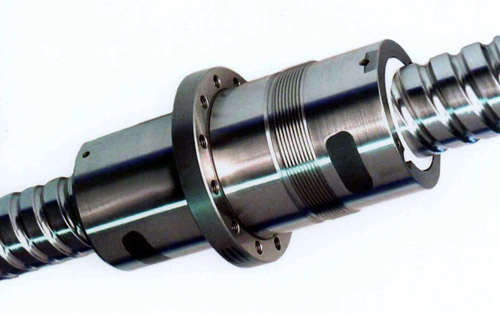

Precision Machining and Ball Screw Repair, Refurbishment, and Reverse Engineering Services.

WELCOME TO

Thread-Craft, Inc.

About Thread-Craft, Inc.

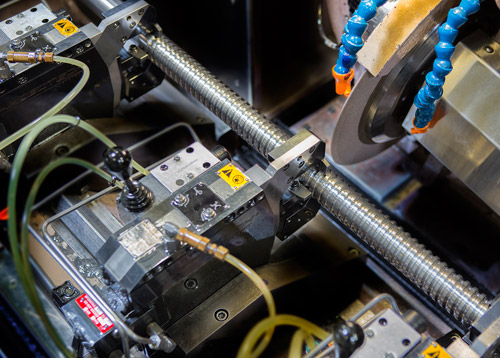

Thread-Craft, Inc. is a manufacturer of mechanical linear movement actuators including ball screw assemblies, acme or lead screws, roller screws and precision spindles. The Company's machining expertise also involves special tool holding devices and precision machine details. Thread-Craft is a full service ball screw and repair facility, capable of evaluating and repairing or remanufacturing products to OEM specifications. In addition, the Company offers precision machining, ID and OD grindi...

Read More