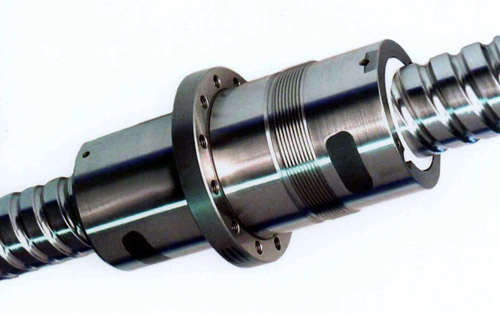

Thread Craft was contracted by JL Lucas, a customer in the precision machine tool remanufacturing industry, to fabricate 4 precision ball screws crucial to their business. Thread-Craft's goal was to do what was necessary to be of service to a customer with a critical deadline. A tremendous amount of machining needed to be completed in 4 weeks, including lathe work, OD grinding, milling, v-threads, and precision internal and external thread grinding. Lead accuracy tolerances of ±.0002" per foot were held. Our internal expedite specialists managed every operation from heat treat through all testing and final inspection. These ball screw assemblies were very particular and unique, not available off the shelf and subsequently very difficult to manufacture. This project was completed in 3 weeks at our facility, and shipped to the client in Waterbury, Connecticut.

Thread Craft specializes in custom designing and machining of ball screw assemblies, as well as emergency repair service. For more about this ball screw machining project or our other capabilities please see the table below or contact us directly.